Low Cost, High Strength, Water-Repellent and Oil-Resistant, Half Decomposed in 2 Months!

The Pain of Disposable Plastic Tableware

Disposable tableware has brought convenience to people’s lives, especially with the development of the takeout industry, which has led to a significant increase in the consumption of disposable tableware. Globally, approximately 16 billion disposable coffee cups are consumed each year, and 1 billion plastic straws are discarded daily. Such massive consumption results in about 8 million tons of plastic waste entering the oceans annually, which conservatively estimates would take 450 years to decompose.

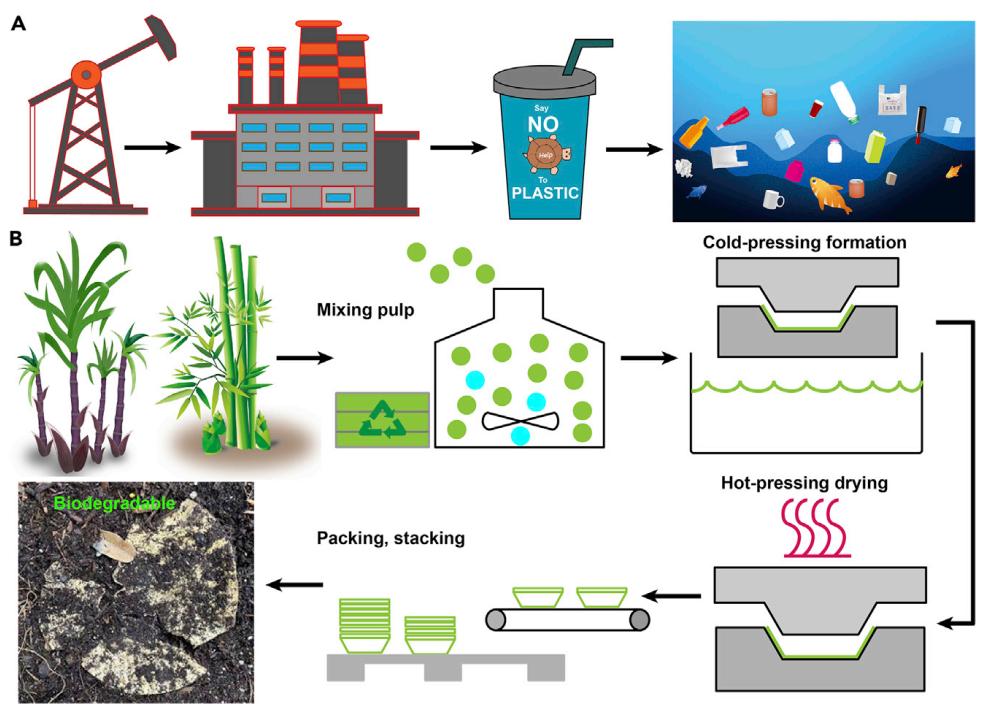

Bamboo fiber and bagasse are woven into disposable tableware (Figure 1).

(A) Illustration of disposable tableware made from petroleum; (B) Illustration of biodegradable tableware produced using bagasse and bamboo fiber.

The research group led by Hongli Zhu at Northeastern University in the United States blended short bagasse fibers with long bamboo fibers, creating a highly interwoven network structure through physical entanglement of the two fibers. Subsequently, disposable tableware was prepared using cold pressing and hot pressing drying processes, which can completely replace plastic and traditional paper tableware.

It decomposes by half in just 60 days.

Figure 2. (A-B) Optical micrographs of mixed fibers at different magnifications; (C-F) SEM images of the tableware surface at different magnifications; (G) Comparison of the biodegradability of mixed fiber tableware with plastic tableware (H).

Through electron microscopy, researchers discovered that the melting of lignin in the fibers and the hydrogen bonding between cellulose molecules tightly bind the fibers together, forming a 3D network that enhances the product’s water resistance and strength.

To study the biodegradability of the tableware, researchers buried them in soil and regularly checked for changes in morphology and weight. After 20 days, yellow fungi appeared on the surface of the tableware, followed by deformation after 30-45 days, and complete loss of shape and gradual disappearance after 60 days. Additionally, the weight of the cup decreased from 7.99 g to 4.18 g after 60 days, almost degrading by half. In contrast, the appearance and shape of polystyrene (PS) plastic tableware remained unchanged after being buried for 60 days. The lead content was only 1/8 of the standard (Figure 3). Study on heavy metal content and water and oil resistance of mixed fiber tableware.

Figure 3. Study on heavy metal content, water resistance, and oil resistance of mixed fiber tableware. (A) Comparison of heavy metal content in tableware; (B-C) Oil resistance of tableware; (D-E) Contact angle and water absorption rate of tableware.

As a manufacturer of biodegradable disposable bowls, ensuring their safety is of utmost importance, especially in terms of heavy metal content such as Pb and As, which should not exceed the standard limits. According to the European Regulation (EC) No 1935/2004 on food contact materials and the Chinese National Food Safety Standard (Food Contact Paper and Paperboard Materials and Articles) GB 4806.8-2016, the content of Pb and As should be below 3.0 mg/kg and 1.0 mg/kg respectively. In this study, the researchers analyzed the Pb and As content in mixed fiber tableware using Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) and found that the Pb content was 0.3633 mg/kg, only 1/8 of the standard value, and no presence of As was detected. In addition to safety, oil resistance and water resistance are also crucial for tableware. The contact angle of mixed fiber tableware with water reached 127°, while it was 0° for secondary fiber molded pulp (SFMP) and filter paper, and 93° for commercial bagasse tableware. The mixed fiber material exhibited excellent hydrophobicity. Furthermore, the water absorption rate of mixed fiber tableware was only 59.4%, compared to 77.5% for commercial bagasse tableware, 149.2% for filter paper, and a staggering 310% for SFMP. This low water absorption is due to the high hydrophobicity and dense structure of mixed fiber. To evaluate the oil resistance of the tableware, the researchers conducted an analysis based on the standard TAPPI 559 pm-96 for pulp and paper industry. They found that the oil resistance of mixed fiber tableware was at level 6, much higher than SFMP (level 1), commercial bagasse tableware (level 4), and filter paper (level 1), demonstrating excellent oil resistance. The tableware remained sturdy even when subjected to a load 380 times its own weight.

Figure 4. Study on mechanical properties of mixed fiber tableware.

Researchers compared the mechanical properties of mixed fiber tableware with PS tableware and found that the tensile strength was 35.0 MPa, at least twice as high as PS plastic cups (15.6 MPa), and the Young’s modulus was 3.25 GPa, significantly higher than PS plastic cups’ 1.40 GPa. A 7.9-gram mixed fiber cup can withstand a weight of 3 kilograms while maintaining its shape, which is a load 380 times its own weight. Carbon dioxide emissions are 97% lower than plastic. The researchers estimated the amount of carbon dioxide emitted during the production process of mixed fiber tableware. It was reported that the carbon dioxide emissions for producing 1 kilogram of foamed PS plastic were 7.36 kilograms. According to statistics from the European Carton and Board Manufacturers Association (Pro-Carton), the emissions for producing 1 kilogram of molded pulp products were 0.22 kilograms. Therefore, the CO2 emissions of molded mixed fiber tableware are 97% lower than PS tableware and 65% lower than traditional disposable paper and PLA plastic tableware. Cost is comparable to PS tableware. In addition to its excellent performance, affordability is also crucial. By comparing statistics from the Plastics Insight-Market Intelligence website, researchers found that the cost of mixed fiber tableware is 4,750 per ton), and close to PS tableware ($2,177 per ton). In conclusion, mixed fiber tableware is a nearly flawless option.

To address the increasingly severe issue of “white pollution,” the research group led by Professor Hongli Zhu at Northeastern University in the United States has developed a rapidly degradable tableware by blending bamboo fiber and bagasse fiber, followed by cold pressing and hot pressing. This tableware can degrade by 48% in just 60 days. The Pb content in the tableware is 0.3633 mg/kg, only 1/8 of the standard limit. It exhibits excellent water and oil resistance. The tensile strength is 35.0 MPa, and the Young’s modulus is 3.25 GPa, significantly higher than PS plastic cups. The production of 1 kilogram of this tableware emits only 0.22 kilograms of CO2, which is 97% lower than PS tableware. The cost is only 2,333perton,comparabletoPStableware (2,177 per ton).Through a comparative analysis of safety, odor, CO2 emissions, cost, biodegradability, abundance, and processability, it is evident that this mixed fiber material-based tableware is nearly perfect in all aspects compared to other materials. If mass production is achieved, the solution to the global “white pollution” problem is within reach.